The story behind our schnapps is a tale of the antipodes melding with European tradition. Schnapps is a quintessential tipple from the Alpine region of Europe where the winters proved too cold for traditional wine production.

It was in the Austrian region of Kitzbühel that wildbrumby founder, Brad Spalding, met his future wife, Monika, whose family had been distilling schnapps long before the couple were born.

Enchanted by this rich distilling heritage, Brad studied the traditional methods and then set out to introduce schnapps to Australia’s Snowy region.

Traditional methods developed over many centuries, combined with exclusive access to home-grown organic fruit and botanicals, are the inspiration behind Wildbrumby’s line of liqueur schnapps much loved here in Australia.

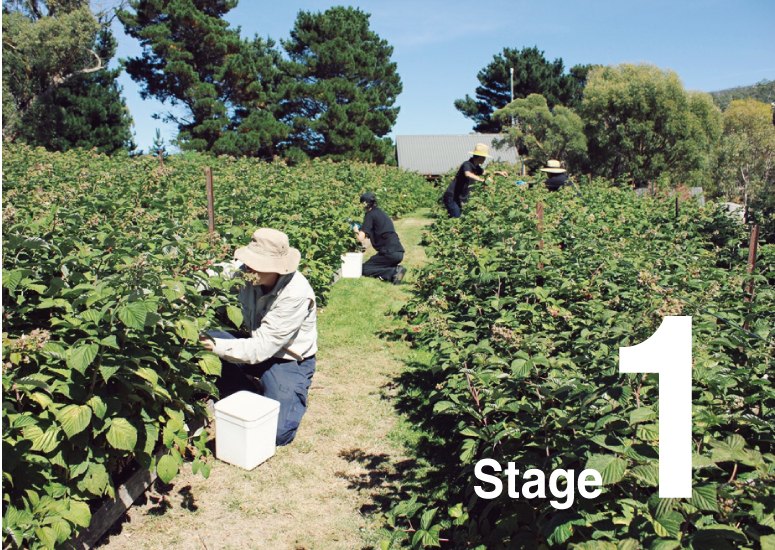

Fruit is sourced from both our adjacent raspberry farm, and from local producers in the Tumut, Batlow and Snowy Mountains region.

Apples, pears, berries and stone fruit are of the highest quality with rich flavours especially suited to making schnapps.

How schnapps is made

Fruit

Firstly, we select the best local fruit we can lay our hands on. We also grow our own organic raspberries in a small patch behind the distillery.

Crushing

The fruit is sliced, diced and machine-processed to remove stones and pips. Crushing the fruit pulp is necessary for fermentation to take place, working as much as possible with the “wild yeast” naturally occurring within the fruit itself.

Fermentation

The crushed fruit pulp is then fermented in vats, at controlled temperatures in a cool room. This normally takes around 4 weeks, but timing really depends on the sugar content of the fruit. The process is very similar to that used in winemaking.

Distillation

The fermented pulp is loaded into our imported still and distilled. This is a critical point in the process, necessary for producing crisp, clean schnapps. The double boiler (at the bottom of the still) boils the fermented pulp (wash) to about 90 degrees. The vapour rises through the 5 chambers, then condenses back into liquid (which is now the spirit), and then passes through the cooling chamber and out of the nozzles at 80-90% in alcohol. This is then blended down with our pristine alpine water and bottled onsite.